TRANSFER OF PRODUCTION PROCESSES

We specialise in our customers’ mass-produced products that are being phased including taking over production systems in order to create space for new projects.

The experience we have gained allows us to quickly carry out projects in an organised fashion.

The initial phase for the transfer period is represented by our own machine park.

After series phase-out, we guarantee delivery of replacement parts.

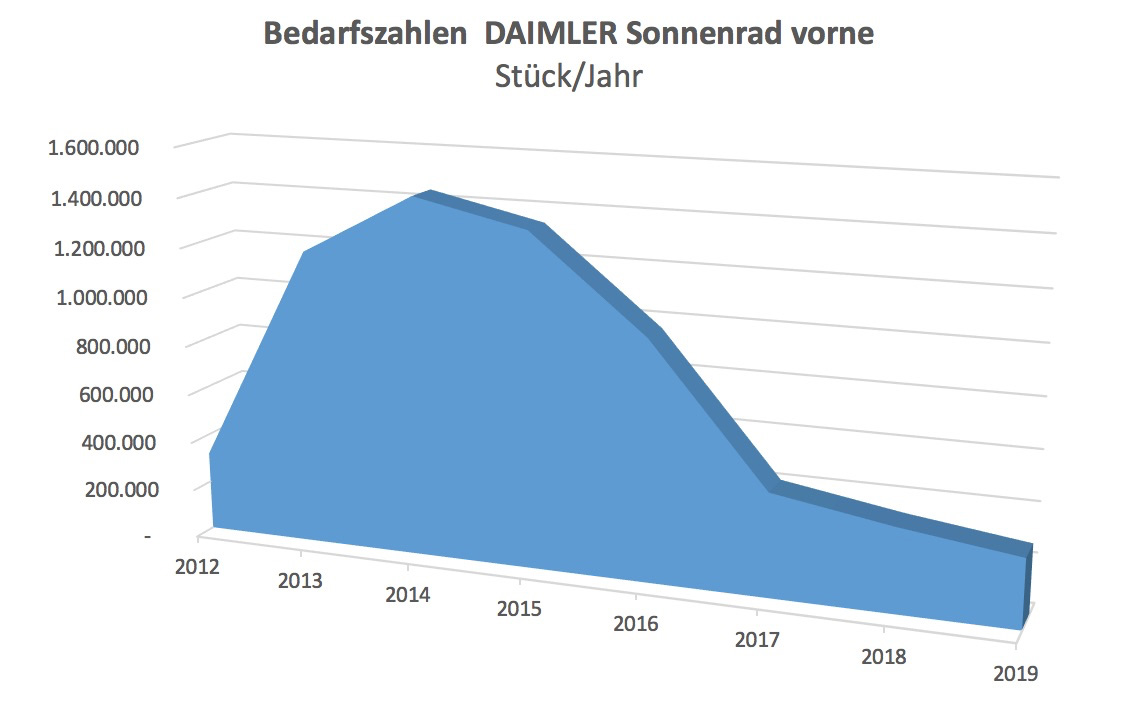

TRANSFER PROJECTS

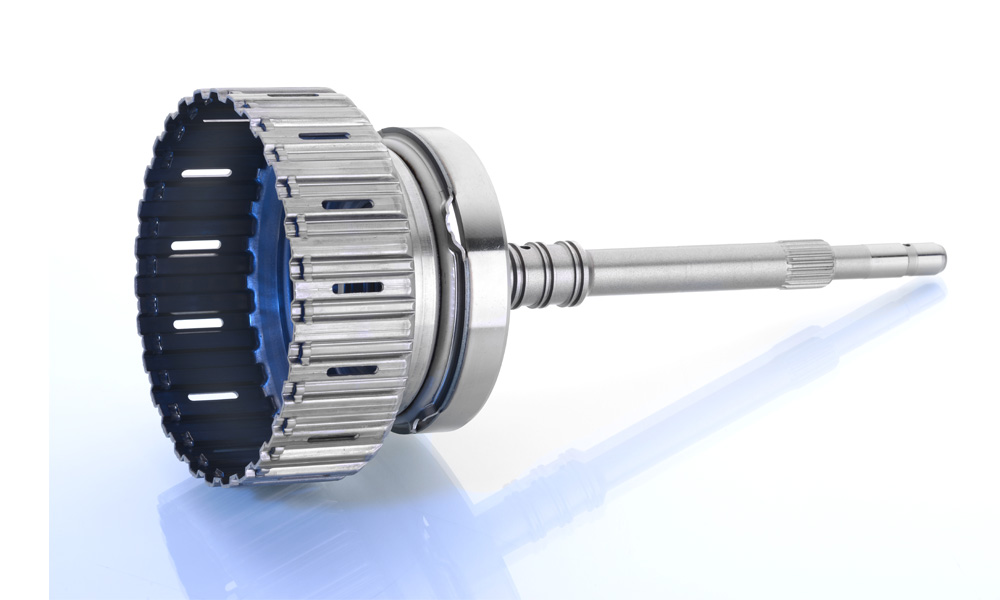

2011 sun wheels NAG 1-2

Transfer area: approx. 1200 m²

Total number of machines: 15

Number of transferred machines: 9

Procurement until start of production: 6 months

2013 driveshafts and driving flanges

Transfer area: approx. 1200 m²

Total number of machines: 16

Number of transferred machines: 8

Procurement until start of production: 6 months

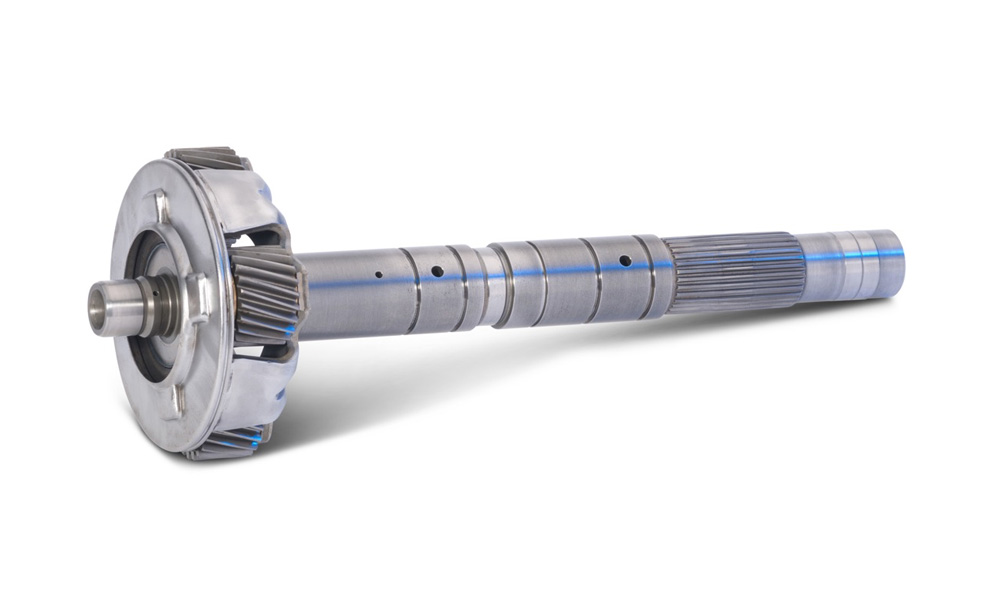

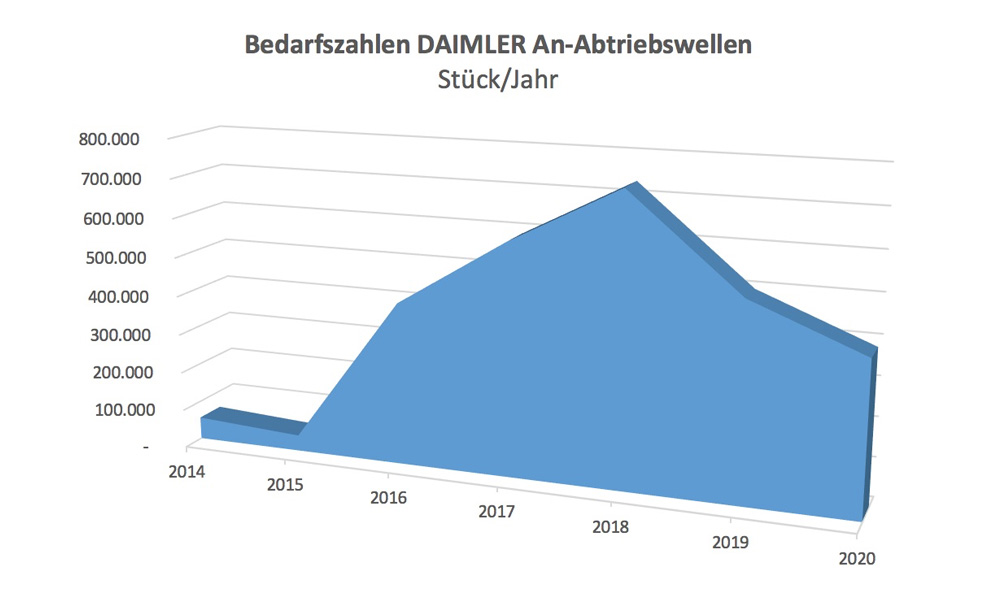

NAG 1+2 driveshafts – pinion shafts

Process description:

2015 Initial production phase for machine transfer on own machine park

10-2015 Start of construction of the new workshop

04-2016 Procurement of the new workshops and start of assembly of the machines taken over

07-2016 Line1 start of mass production – soft machining of driveshaft

08-2016 Line2 start of mass production – hard machining of driveshaft

02-2017 Line3 start of mass production – laser welding and assembly of driveshaft

10-2016 Disassembly of pinion shaft machines at customer’s location

05-2017 Line4 start of mass production – soft machining of pinion shaft

06-2017 Line5 start of mass production – hard machining of pinion shaft

07-2017 Line6 start of mass production – laser welding and assembly of pinion shaft

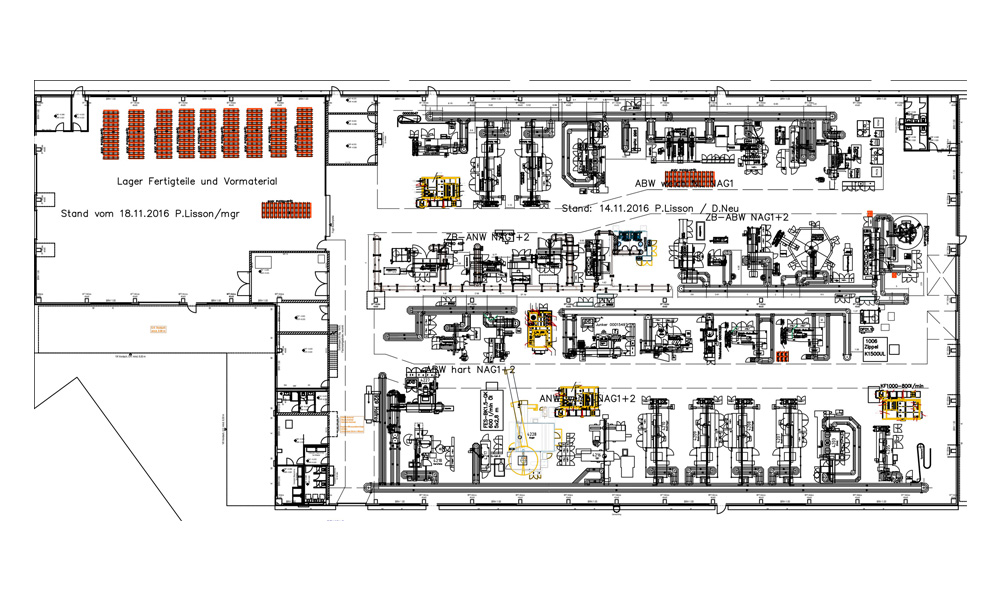

Transfer area: construction of production hall with 5400 m² + 1400m² in available halls

Total number of machines: 66

Number of transferred machines: 46

Procurement until start of production: approx. 18 months

Layout for New Construction