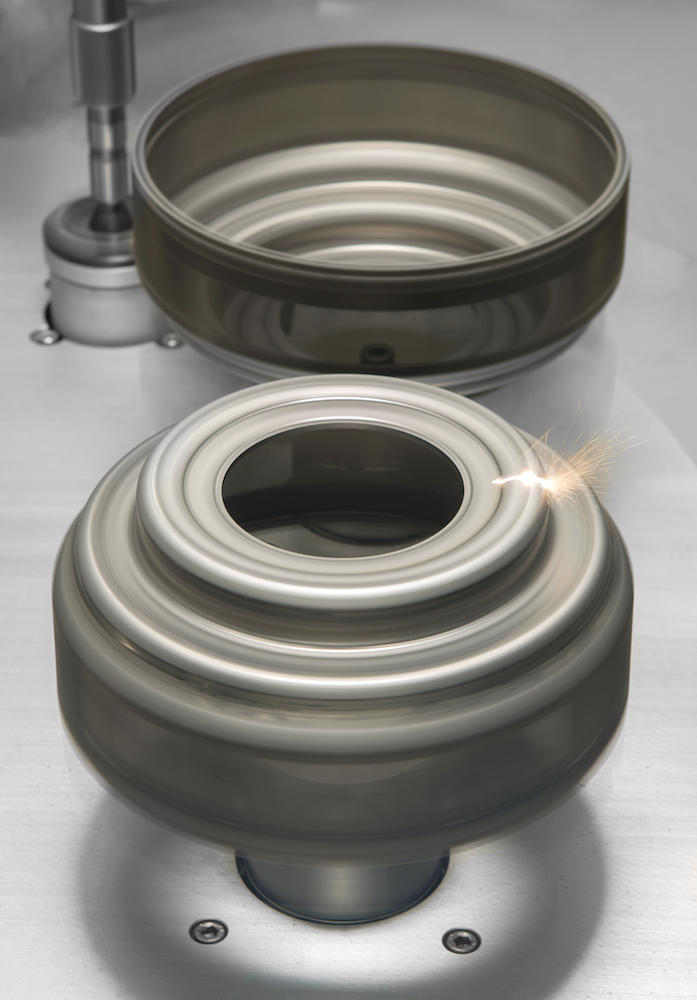

LASER WELDING JOINING

The components used will be prepared with the most modern methods for the laser welding joining process. Pretreatment will be carried out using a laser that simply partially cleans the necessary welding surfaces. Through laser cleaning, a weld seam of the highest quality and strength can be produced. This process is especially effective and environmentally friendly.

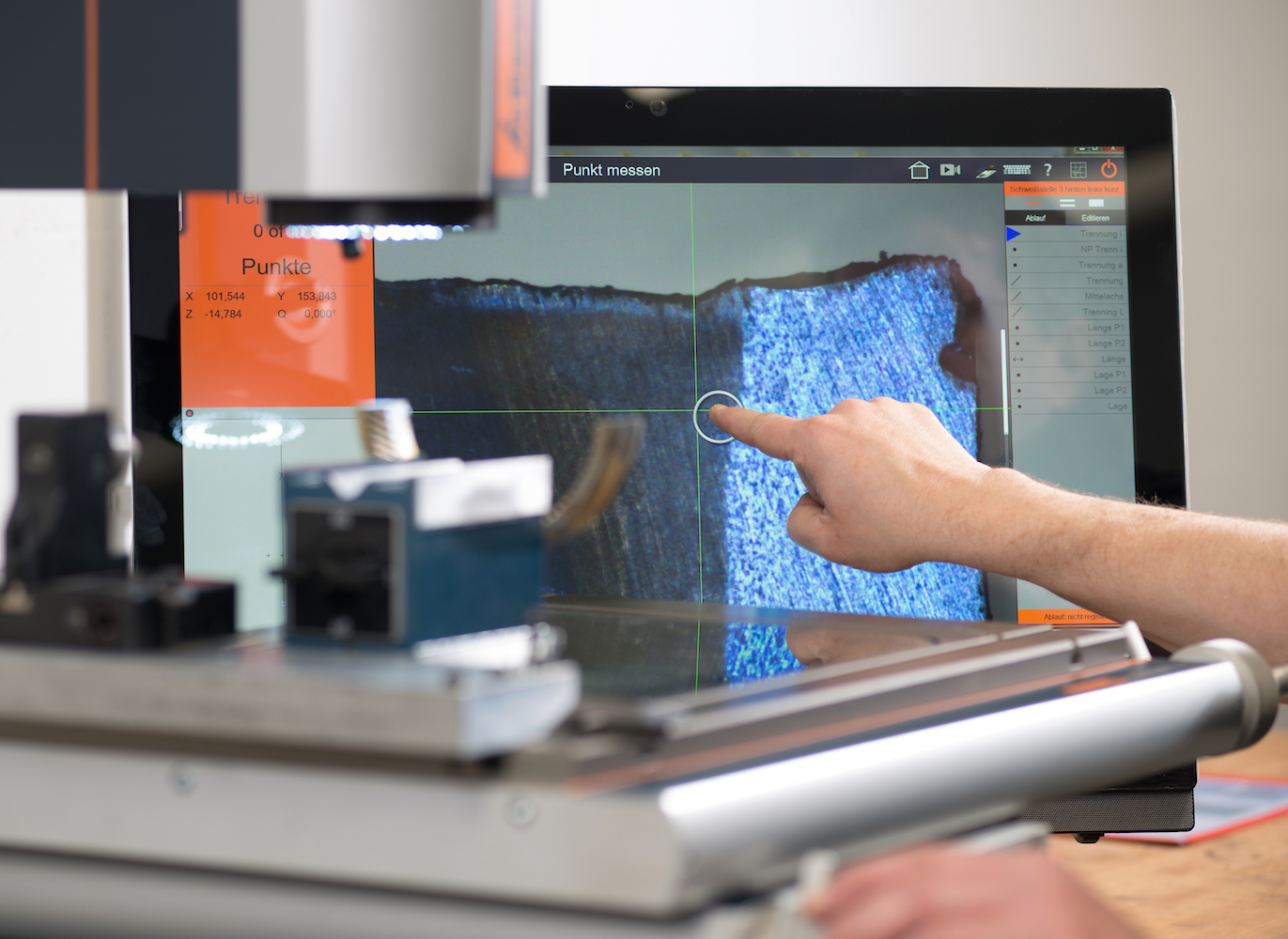

In the laser welding operations carried out, up to four components are connected to each other, meeting the highest quality standards. These standards can be attained through process and procedure optimisation. To ensure quality, in-house created cutting patterns are evaluated and archived multiple times a day.